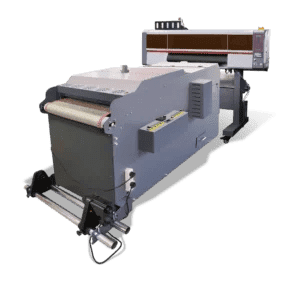

Direct-to-film printing technology is quickly becoming the preferred method for printing high-quality images and graphics on a variety of substrates. This method is considered the best due to several key advantages it offers over traditional printing methods.

First, direct-to-film printing technology allows for a higher level of precision and detail in the printed image. This is because the ink is printed directly onto the film, rather than being transferred onto the film through a separate printing plate. This results in sharper, more accurate images with less distortion or blurring.

In addition, direct-to-film printing technology is also more efficient and cost-effective than traditional printing methods. The process is faster and requires less labor, resulting in lower costs and faster turnaround times.

Another advantage of direct-to-film printing technology is its ability to print on a wide range of substrates, including plastic, metal, and paper. This allows for greater flexibility in the types of materials that can be used for printing, resulting in a wider range of applications for the technology.

Lastly, the process of direct-to-film printing technology is also more environmentally friendly than traditional printing methods. It uses less ink and generates less waste, making it a more sustainable option.

- Another example of the advantages of direct-to-film printing technology can be seen in the packaging industry. Brands are increasingly using this method to print high-quality images and graphics on packaging materials, such as plastic and metal containers. The precision and detail provided by direct-to-film printing technology allows for vibrant and eye-catching packaging designs that help to attract customers and increase brand awareness.

- In the graphic arts industry, direct-to-film printing technology is also becoming a popular choice for printing high-quality posters, banners, and trade show graphics. The ability to print on a wide range of materials, such as vinyl, polyester, and polypropylene, allows for the creation of durable, long-lasting displays that can withstand the rigors of travel and outdoor use.

- In the automotive industry, Direct-to-film printing technology is also used for printing on various car parts like headlamps, tail lights, and various plastic parts. The high precision and detail provided by direct-to-film printing technology allows for precise and accurate color matching, ensuring that the finished product is visually appealing and consistent with the original design.

- In the medical device industry, Direct-to-film printing technology is used to print on medical devices like surgical instruments, diagnostic equipment, and implants. The precision and detail provided by direct-to-film printing technology ensures that the finished product is visually appealing and consistent with the original design, while also meeting the strict regulatory requirements of the medical industry.

Overall, direct-to-film printing technology is the best option for high-quality, precise, efficient, and cost-effective printing on a variety of substrates. Its ability to print on a wide range of materials and its environmentally friendly nature makes it a versatile and sustainable option for various industries.